Labor Practices

Total Employees

The total number of employees year over year is as follows:

- 2024 : 1.061 employees

- 2023 : 1.163 employees

- 2022 : 1.283 employees

- 2021 : 1.363 employees

- 2020 : 1.444 employees

Freedom of Association (2024)

Wika Beton is committed to ensuring that all aspects of labor practices are carried out with respect to fair and transparent human rights principles. The company recognizes the importance of creating a healthy, safe, and respectful work environment that upholds the fundamental rights of employees. As part of its corporate social responsibility, Wika Beton continues to strive to meet high labor standards through policies that support worker welfare and equality in the workplace.

-

1. Ensuring fair wages equivalent to or higher than the estimated cost of living or applicable standards

Wika Beton ensures fair compensation by providing wages above the Regional Minimum Wage (UMR) in line with the company's commitment to offering remuneration that matches the competence, contribution, and responsibilities of employees.

-

2. Worktime Regulations

Wika Beton sets a maximum worktime limit of eight hours per day or forty hours per week with five working days, in accordance with applicable laws and the Collective Labor Agreement (PKB). The company is committed to providing an adequate work-life balance for employees.

-

3. Ensuring Employees are Paid for Overtime Work and Monitoring Employee Work Hours

Wika Beton monitors employees who will perform overtime by completing an Overtime Authorization Letter (SPL) that is verified by the direct supervisor, with work targets aligned with daily workloads and applicable regulations. The Human Capital Division monitors work hours by using the Enterprise Resource Program (ERP) system, in accordance with the company's overtime policy, which automatically calculates the overtime pay employees are entitled to.

-

4. Regularly communicate with employee representatives regarding working conditions

WIKA BETON maintains strong communication with employees through regular bipartite meetings with the Workers' Union (PPWB) to discuss welfare and labor-related issues. In 2023, PPWB held a National Congress to address key labor issues, and in 2024, meetings focused on revising the Collective Labor Agreement (PKB) for 2025-2026 and discussing annual employee incentives.

-

5. Equal Remuneration Between Men and Women

Wika Beton is also committed to ensuring that all employees, regardless of gender, receive fair and non-discriminatory remuneration.

-

6. Annual Leave Entitlement

Wika Beton grants annual leave rights of twelve working days with full pay and assistance for leave expenses. This policy supports a balanced work-life relationship for employees.

Employees Freedom of Association

Non-Represented Employees

Female Employee Representation 2024

Female Employees at level Senior

Senior Management (BOD-1)

Female Employees at level Middle

Middle Management (BOD-2)

Female Employees at level Junior

Junior Management (BOD-3)

Female Employees at level All Management Levels

All Levels of Management

Employees Based on Ethic Diversity 2024

Javanese

672 people

(63.34 %)

Javanese

672 people

(63.34 %)

Sundanese

154 people

(14.51 %)

Sundanese

154 people

(14.51 %)

Malay

48 people

(4.52 %)

Malay

48 people

(4.52 %)

Batak

47 people

(4.43 %)

Batak

47 people

(4.43 %)

Minangkabau

37 people

(3.49 %)

Minangkabau

37 people

(3.49 %)

Others

103 people

(9.71 %)

Others

103 people

(9.71 %)

Human Capital Management

Employee Development Programs

- Satria Pratama (mandatory training program BOD-2)

- Effective Communication Skill (Public Speaking)

- Problem Solving Decision Making (PROSDEM)

- Strategic Thinking & Business Acumen

- Advance Leadership Program (ALP)

- Postgraduate program (S2/S3)

- Quality Excellent Activity

Investing in employee development not only enhances the skills of each individual but also ensures that human capital can work effectively to create value for the company. To assess the impact of various HR programs, WIKA Beton uses the HROI approach as the primary measure of labor management efficiency. HROI calculates the financial contribution of HR programs to the company's profit by comparing total company revenue with labor costs. Through this approach, the company can determine how much HR policies—such as training, compensation, and welfare programs—truly add value to the business.

Human Capital Return On Invesment (HCROI) Worksheet

| No | Year | Classification | HCROI | Total Employees | ||

|---|---|---|---|---|---|---|

| Sales Revenue | Operational Expenses | Employee Expenses | ||||

| 1 | 2021 | 4.458.987.837.356 | 117.560.439.921 | 41.542.303.210 | 105,51 | 1.363 |

| 2 | 2022 | 6.003.788.032.167 | 117.294.441.316 | 46.651.573.095 | 127,18 | 1.283 |

| 3 | 2023 | 4.203.170.642.940 | 131.577.565.662 | 51.840.483.830 | 79,54 | 1.163 |

| 4 | 2024 | 4.896.024.340.364 | 160.276.919.776 | 57.153.982.358 | 83,86 | 1.061 |

Sharing Session : Knowledge Level Up

PT Wijaya Karya Beton Tbk. conducts Engineering Sharing Sessions as a structured knowledge-development initiative aimed at strengthening employee technical capabilities, supporting continuous learning, and enhancing operational efficiency across the Company. Through the exchange of best practices, cross-functional insights, and real project experiences, this program reinforces our commitment to engineering excellence, quality improvement, and risk-aware decision-making. By empowering our workforce with up-to-date engineering knowledge and practical problem-solving skills, WIKA Beton ensures a future-ready organization capable of driving sustainable performance and long-term value creation.

PT Wijaya Karya Beton Tbk has established a digital transition program as part of its efforts to enhance operational efficiency and strengthen asset management practices, one of which is demonstrated through the socialization and implementation of the Computerized Maintenance Management System (CMMS). Based on the training and socialization activities presented in the CMMS Launching program, the Company has systematically introduced digital solutions integrated with the Fixed Asset Management System (FAMS) and Total Productive Maintenance (TPM). This initiative enables real-time monitoring of equipment and molds, Controlling maintenance and repair cost, Evaluate the status and condition of equipment and molds, Digitization to improve data accuracy and speed up reporting, and Data integration from and to other ERPs. Through this digital transition, the Company has shifted from manual and fragmented processes toward an integrated digital ecosystem.

In addition to the CMMS program, several digital transformation initiatives have been implemented to support the digitization and integration of business processes. Other initiatives include the implementation of ERP, digital document management and e-signature, production line automation through the CCMS, transport management systems, and digital precast identification. Collectively, these initiatives demonstrate PT Wijaya Karya Beton Tbk transition from manual processes to an integrated digital ecosystem that supports operational efficiency and data-driven decision-making.

Employee Support Programs

- Facilitating comprehensive health examinations (medical check-ups/MCUs) for all employees

- Organizing sharing sessions by company doctors regarding health

- Sports activities such as gymnastics, badminton, mini soccer, futsal, tennis, running mini scale, bicycle race, yoga

- WTON Mental Health Programs

Employee Turnover Rate (%)

Trend of Employee Wellbeing

Note:

The employee turnover rate during the reporting period was mainly due to terminations of employment, predominantly of employees entering

retirement, as well as the implementation of corporate eficiency policies as a strategic measure to adjust the organization in order to maintain

operational efectiveness and the company's performance sustainability.

New Employee Composition and Employee Turnover by Gender

| Gender | 2024 | 2023 | 2022 | 2021 | ||||

|---|---|---|---|---|---|---|---|---|

| New Employees | Leaving Employees | New Employees | Leaving Employees | New Employees | Leaving Employees | New Employees | Leaving Employees | |

| Male | 1 | 98 | 1 | 116 | 21 | 100 | 2 | 82 |

| Female | 1 | 4 | 0 | 5 | 4 | 5 | 1 | 2 |

| Total | 2 | 102 | 1 | 121 | 25 | 105 | 3 | 84 |

Note:

- In 2021, there were three employee transfers from the WIKA Group.

- In 2022, there were twenty-one new employees, one employee of WIKA Beton's subsidiary who has been naturalized, and three employees transferred from the WIKA Group.

- In 2023, there was one employee transfers from the WIKA Group.

- In 2024, there were two employee transfers from the WIKA Group.

New Employee Composition and Employee Turnover by Work Area

| Work Area | 2024 | 2023 | 2022 | 2021 | ||||

|---|---|---|---|---|---|---|---|---|

| New Employees | Leaving Employees | New Employees | Leaving Employees | New Employees | Leaving Employees | New Employees | Leaving Employees | |

| Head Office | 1 | 18 | 0 | 17 | 14 | 14 | 3 | 11 |

| Precast Concrete Product Plant | 0 | 59 | 1 | 85 | 0 | 66 | 0 | 58 |

| Sales Area | 0 | 10 | 0 | 8 | 11 | 19 | 0 | 11 |

| Operation Unit | 0 | 13 | 0 | 8 | 0 | 2 | 0 | 2 |

| Subsidiary | 1 | 2 | 0 | 3 | 0 | 4 | 0 | 2 |

| Total | 2 | 102 | 1 | 121 | 25 | 105 | 3 | 84 |

New Employee Composition and Employee Turnover by Age Group

| Age Group | 2024 | 2023 | 2022 | 2021 | ||||

|---|---|---|---|---|---|---|---|---|

| New Employees | Leaving Employees | New Employees | Leaving Employees | New Employees | Leaving Employees | New Employees | Leaving Employees | |

| 18-30 | 2 | 6 | 0 | 9 | 17 | 17 | 0 | 13 |

| 31-40 | 0 | 23 | 0 | 18 | 5 | 20 | 2 | 8 |

| 41-50 | 0 | 7 | 1 | 5 | 3 | 13 | 0 | 16 |

| >50 | 0 | 66 | 0 | 89 | 0 | 55 | 1 | 47 |

| Total | 2 | 102 | 1 | 121 | 25 | 105 | 3 | 84 |

Employee Turnover from 2021 to 2024

| Description |

2024 Total |

2023 Total |

2022 Total |

2021 Total |

|---|---|---|---|---|

| New Hires / Transfers from WIKA Group | 2 | 1 | 25 | 3 |

| Deceased | 6 | 3 | 3 | 1 |

| Resigned | 18 | 25 | 31 | 21 |

| Retired | 55 | 86 | 42 | 40 |

| Company Decision | 22 | 6 | 27 | 14 |

| WIKA Group Transfers | 0 | 0 | 1 | 7 |

| Appointed as Company Executive | 1 | 1 | 1 | 1 |

The employee turnover data for 2021 to 2024 presented in the ESG Dashboard is the latest data that has been updated regularly, and serves as a supplement to the data listed in the company's Sustainability Report and Annual Report.

Occupational Health & Safety

OHS Programs

As part of our firm commitment to building a strong Occupational Health and Safety (OHS) culture, the company implements a series of comprehensive and continuous programs designed to ensure the safety, health, and environmental responsibility of all employees and stakeholders.

Our key OHS programs include:

1. HSE Training and Awareness for All Employees

Regular training and awareness programs are conducted for all employees to enhance their understanding and competence in occupational health, safety, and environmental management. These sessions also include topics on energy efficiency, pollution prevention, and sustainable resource use, aligning with the company's commitment to environmental stewardship and ESG principles.

2. QHSE Patrol by the Board of Directors and Commissioners

Regular QHSE patrols are carried out directly by the Board of Directors and Commissioners to ensure that quality, health, safety, and environmental standards are properly implemented and continuously improved across all operational areas.

3. Daily Safety Toolbox Meeting

Short, focused discussions are held daily before work begins to communicate potential hazards, safety precautions, and key tasks for the day. These sessions foster effective communication among team members and help ensure that everyone is fully prepared to work safely.

4. Regular Safety Inspections

Routine inspections are conducted on work environments and equipment to identify potential risks, ensure operational integrity, and maintain compliance with environmental and safety standards. This proactive approach helps prevent incidents and supports the company's goal of continuous improvement in workplace safety and sustainability.

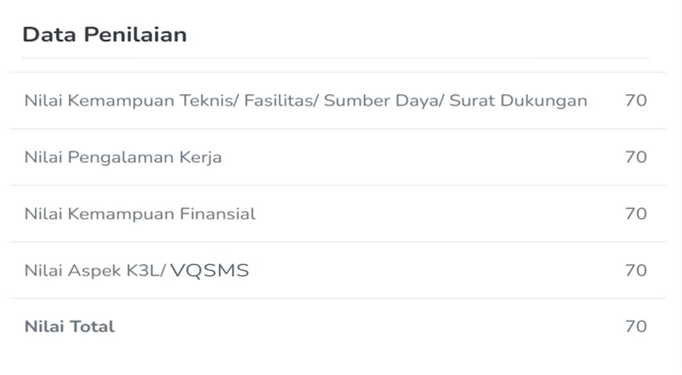

5. HSE-Based Vendor Selection Program

The company applies HSE performance as a key criterion in vendor selection and evaluation processes. Vendors are assessed based on their commitment and capability in implementing occupational health, safety, and environmental management systems.

- Vendors that have valid HSE-related certifications such as ISO 45001 (Occupational Health and Safety Management System), ISO 14001 (Environmental Management System), or SMK3 (Indonesia Government Regulation No. 50/2012), and can demonstrate effective implementation of HSE procedures, are awarded a score of 90.

- Vendors without these certifications, or who have yet to implement a formal HSE management system, receive a score of 50.

As a mandatory requirement before working with the company, all vendors are required to sign an Integrity Pact, which includes a strict commitment to comply with the company's HSE policies and standards. This ensures that every partner aligns with the company's values regarding safety, environmental responsibility, and ethical business conduct. This scoring and integrity commitment framework ensures that vendor selection not only considers technical and financial capability but also prioritizes partners who uphold strong safety and environmental standards in line with the company's HSE commitment.

6. Emergency Drill & Simulation Program

Periodic emergency response drills are conducted to test readiness and strengthen employee capabilities in managing emergency scenarios, including fire incidents, chemical spills, bomb threats, civil unrest and natural disasters. These simulations ensure that all personnel understand their roles and can respond effectively in real situations.

7. Audit Program

Independent external audits are regularly performed to evaluate the effectiveness of the company's HSE management system. The audit results serve as a foundation for continual improvement, transparency, and alignment with international standards and best practices.

Through these integrated programs, the company aims to strengthen its safety culture, promote environmental awareness, and maintain a safe, healthy, and sustainable workplace across all operations.

Lost-Time Injury Frequency Rate (LTIFR) - Employees

Lost-Time Injury Frequency Rate (LTIFR) - Contractor

Fatalities - Employees

Fatalities - Contractor

Customer Relation

Customer Relation

Wika Beton has set a company KPI target of 4.20 in 2024 for customer satisfaction as part of its commitment to maintaining and improving customer relationships. This target reflects the company’s focus on sustaining a high level of satisfaction and ensuring a positive customer experience. With this target, the company continues to strive to provide the best service and improve the Customer Satisfaction Index

Community Relation

Stakeholder Engagement Programs

- WIKA BETON Scholarship Program Building the Future

- Elementary School Badminton Court Program from Porous Concrete

- Biodiversity Conservation through Sustainable Synergy Program in Pari Island, Jakarta

To handle input and complaints from stakeholders, the Corporate Secretary provides a communication forum and complaint service accessible through several channels, including email at sekper@wika-beton.co.id and telephone at (+6221) 819 2802.

Every complaint received will be processed quickly, professionally, and resolved collaboratively between the company and stakeholders, prioritizing the principles of openness, responsibility, and mutual respect.

Stakeholder Engagement Strategy

Pillar 1: Employees and Internal Teams

- Continuous dialogue through internal forums and feedback mechanisms

- Employee development programs in the context of industrial transformation

- Occupational health and safety standards that exceed national regulations

- Transparent communication regarding the Company’s sustainability vision

Pillar 2: Local Communities and Society

- CSR and TJSL programs that support local economic empowerment

- Early-stage consultations prior to the commencement of construction projects

- Mitigation of environmental and social impacts arising from production activities

- Partnerships with local civil society organizations

Pillar 3: Customers and Business Partners

- Transparency in product specifications and concrete quality standards

- Technical support and education on sustainable practices

- Mutually beneficial and sustainable partnership programs

- Acceptance of feedback to improve services and products

Pillar 4: Government and Regulators

- Compliance with environmental and occupational safety standards

- Active contribution to the development of construction material industry standards

- Transparency in reporting environmental and social impacts

- Constructive dialogue in the implementation of new regulations

Pillar 5: Investors and Financial Stakeholders

- Comprehensive and verified ESG performance reporting

- Transparency in climate and environmental risk mitigation strategies

- Regular communication on long-term value creation

- Engagement in sustainable governance and finance

Wika Beton’s Specific Commitments to the Construction Materials Sector

-

•

Sustainable Quality Products: WIKA Beton is committed to developing concrete and precast products that meet international standards while minimizing carbon footprint throughout the product life cycle.

-

•

Innovation and Green Technology: WIKA Beton invests in environmentally friendly production technologies, including the use of alternative fuels and recycled materials.

-

•

Supply Chain Transparency: WIKA Beton ensures traceability and the implementation of sustainability practices throughout the supply chain.

-

•

Human Capital Training and Development: WIKA Beton conducts continuous training programs for employees and partners on ESG practices in the construction industry.

-

•

Industry Collaboration: WIKA Beton actively participates in industry associations to establish sustainability standards and best practices.

Monitoring And Evaluation

WIKA Beton conducts continuous monitoring of the effectiveness of this policy through:

- Periodic stakeholder satisfaction surveys

- Transparent review and reporting of ESG performance

- Internal and external audits to ensure policy compliance

- Strategic adjustments based on feedback and changes in the business context